Official debut! The first set of 50 standard square alkaline water electrolysis hydrogen production system independently developed by CPU Hydrogen is offline

Time:2022/1/24 8:17:04 Tag:Hydrogen production equipment, system, electrolyzer, independent research and development, CPU

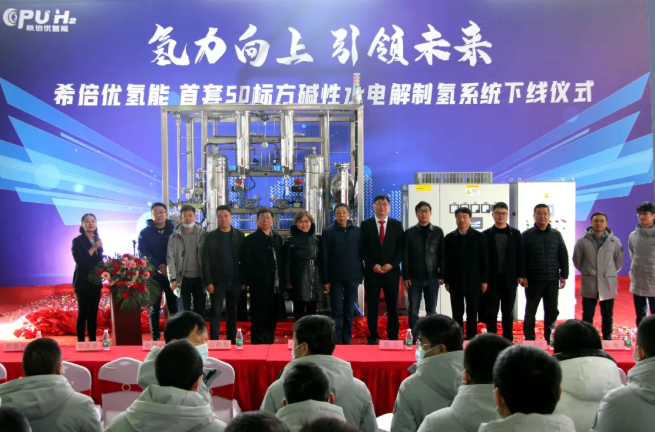

On January 22, CPU Hydrogen Power Technology(Suzhou)Co. ,Ltd. (hereinafter referred to as "CPU Hydrogen") held a conference in Suzhou, Jiangsu with the theme of "Hydrogen Power Leading the Future" and the first set of 50 standard square alkali of CPU Hydrogen. The offline ceremony of the hydrogen production system of sexual water electrolysis.

▲ wonderful moment

Li Liuguan, general manager of CPU Hydrogen, Xu Shangguo, deputy general manager of CPU Hydrogen, Zhao Qite, technical director ofCPU Hydrogen, and Mi Yue, executive chairman of Shanghai New Energy Industry Association, attended the meeting, and invited representatives of relevant units to jointly Participate in witnessing.

General Manager Li Liuguan expressed his warm welcome and heartfelt thanks to everyone on behalf of CPU Hydrogen. He introduced that CPU Hydrogen will develop two types of electrolyzers in 2021, which are economical applications in the hydrogen refueling station system, and multi-cell combined high-current density electrolyzers in the field of new energy, which are comprehensive in terms of materials and processes. promote.

In order to further improve the core competitiveness, CPU Hydrogen will continue to focus on the "hard technology" of hydrogen production! Finally, after more than 4 months of hard work, the first 50-standard alkaline water electrolysis hydrogen production system was officially launched today!

At the event site, as the red silk was gradually unveiled, a skid-mounted main equipment with a height of about 3 meters came into view! This is the main equipment of the 50-square-meter alkaline electrolysis water hydrogen production system, including the core electrolyzer, post-processing system and control cabinet. In addition, auxiliary equipment such as power supply, cooling system, and pure water machine were also unveiled.

▲ unveiling ceremony

According to reports, the 50-standard alkaline water electrolysis hydrogen production system that has been offline this time can realize automatic control of equipment and real-time monitoring of data, and the operation efficiency is more intuitive; the equipment has also been optimized and improved in traditional materials, structure and design. The power consumption and current density can be compared with the domestic first-line level.

"The 50-square-meter alkaline electrolysis water hydrogen production system is a very important phased achievement of CBP! It signifies that CBP has the ability to provide customers with turnkey products and system solutions." Li Liuguan said in his speech that hydrogen produced by electrolysis of water can not only be used for energy saving and emission reduction in the transportation field, but also in industry and other new energy fields. Unremitting efforts have been made in the commercial operation and large-scale application of "green hydrogen".

▲ Equipment visit

▲ Group photo of guests

According to reports, CPU Hydrogen has started the production of the latest generation of the international advanced level 1000 standard square alkaline water electrolysis hydrogen production system, which is expected to be unveiled at the end of May this year at the earliest! In addition, CPU Hydrogen has also reserved cutting-edge technologies. In the future, it will develop a new type of electrolyzer system with small size, low cost, low energy consumption, high electrical density, full automation and dynamic working ability, and plans to expand the production capacity of the new factory. to 1GW of alkaline electrolyzer production capacity.

In the critical period and window period to achieve the goal of "carbon peak and carbon neutrality", CPU Hydrogen will actively fulfill its corporate responsibility, and continue to develop and innovate by giving full play to its own advantages, so as to better provide systematic support to partners. Hydrogen production solutions and equipment from water electrolysis contribute to the promotion of emission reduction and energy structure transformation.