Solutions

- Laboratory&University

- Hydrogen in power plants

- Hydrogen Production and Refueling Station

- Large-scale on-site hydrogen production

- Hydrogen Production using Solar Energy

- Hydrogen Production using Wind Energy

- Hydrogen production from other renewable electric power

- Distributed hydrogen generation cogeneration

Laboratory&University

1.Element overview

Hydrogen is the most widely distributed and abundant chemical element in the universe. The element symbol H is the first in the periodic table. The usual elemental form of hydrogen is hydrogen, a gas composed of diatomic molecules. Hydrogen is the lightest gas, colorless, odorless, and highly combustible.

The hydrogen molecule is relatively stable under most conditions, but the hydrogen atom is extremely reductive at high temperatures. With the exception of the noble gases, almost all elements can form compounds with hydrogen. Hydrogen is the third most abundant on the surface of the Earth, but most of it exists in the form of hydrogen compounds or hydrides. To obtain free hydrogen, we need to use physical or chemical methods to break down the hydrogen from these substances.

2.N ways of hydrogen production

Hydrogen production from coal, natural gas, alcohol conversion, by-product gas purification and recovery, water electrolysis, ammonia, biomass, nuclear energy, solar thermochemical hydrogen, solar water photolysis hydrogen ... According to different production sources, the World Energy Council classifies hydrogen as “gray hydrogen”, “ blue hydrogen” and “green hydrogen”.

3. What is hydrogen production by water electrolysis?

Hydrogen production by water electrolysis refers to the generation of hydrogen after introducing current into electrolyte aqueous solution, and its technical routes are mainly divided into three types: hydrogen production by alkaline water electrolyzer, hydrogen production by proton exchange membrane water electrolyzer and hydrogen production by solid oxide water electrolyzer. Among them, the lowest cost and the most mature technology is hydrogen production in alkaline water electrolyzer.

"CPU H2" mainly uses alkaline electrolyzed water hydrogen production technology to design and manufacture electrolyzed water hydrogen production system.

Hydrogen production technology by alkaline water electrolysis is the process of hydrogen production by water electrolysis in alkaline electrolyte environment. Under the action of direct current, the electrons of the positive electrode will "run" to the negative electrode, and the water and electrons near the negative electrode will undergo hydrogen evolution reduction reaction to produce hydrogen and hydroxide ions; When hydroxyl ions pass through the diaphragm and "run" near the anode, they will lose electrons and undergo oxygen evolution and oxidation reaction to generate water and oxygen. "CPU H2" can inherit the traditional design of electrolyzer and innovate at the same time. Through the research and development of new structure design, new diaphragm and electrode catalyst, the system performance is continuously improved. At the same time, the company has technical reserves of new hydrogen production technologies such as PEM and AEM.

4.The composition of electrolytic hydrogen production equipment

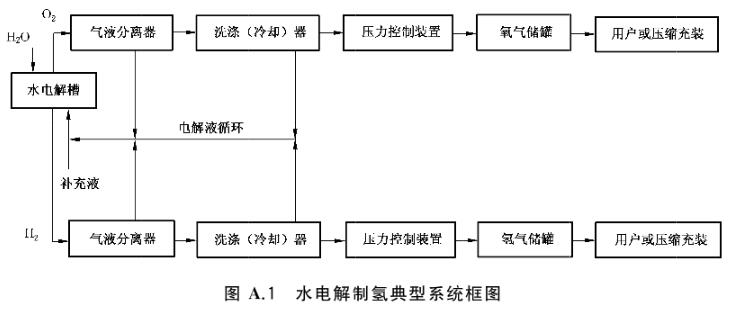

Water electrolysis hydrogen production system can be divided into normal pressure type and pressure type, and its main equipment is water electrolyzer. The water electrolysis cell is composed of several electrolysis cells, each of which is composed of electrodes, diaphragms and electrolyte solutions, thus forming various shapes and specifications of water electrolysis hydrogen production systems. The structure of water electrolysis hydrogen production system is determined by the working pressure of hydrogen production device, the use of hydrogen (oxygen) gas, the purity of gas and its allowable impurity content.

With the continuous development of hydrogen energy industry, more and more colleges and universities began to add related majors to train professionals in hydrogen energy industry. Small hydrogen production electrolyzer and its supporting auxiliary equipment will become the supporting basic equipment for professional laboratories in colleges and universities.