Video visit to the on-site operation of

Time:2023/2/7 Tag:CPU H2,Hydrogen production equipment, field shooting

How to operate the hydrogen production equipment? What is the energy consumption of the system? Can the purity of hydrogen meet the requirements? ..... There are many questions. Now, don't worry about it. "CPU H2" can open an online video tour to let you know about the CPU hydrogen production system in an all-round way without leaving home.

Hydrogen energy, as a flexible and efficient secondary energy with rich application scenarios, is an ideal interconnection medium to promote the clean and efficient utilization of traditional fossil energy and the large-scale development of renewable energy, and it is also the best choice to realize large-scale deep decarbonization in transportation, industry and construction.

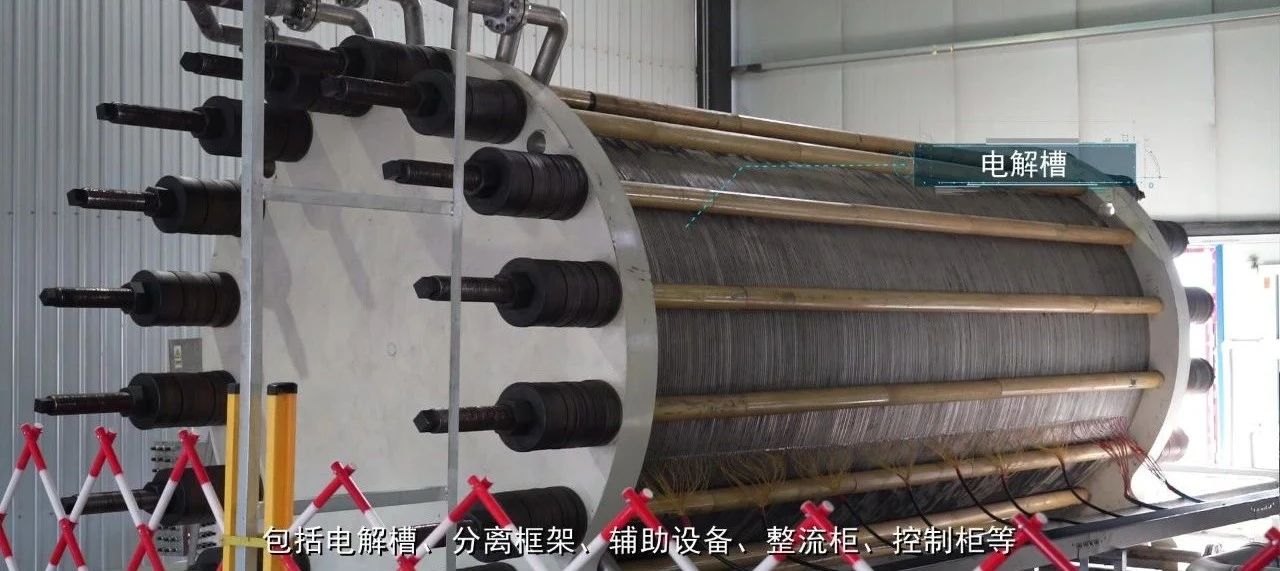

Among them, the electrolytic cell is the "heart" of the whole hydrogen production system, which is used to decompose water into hydrogen and oxygen.

- The electrolytic cell is formed by regularly laminating a plurality of unit cells into a cell body of the electrolytic cell.

- Application of advanced filter-pressing structure

- A new type of integrated bipolar plate is adopted to minimize the ohmic loss of electronic conductors.

- The electrolyzer can change within the range of 20%-110% of rated load.

Among them, the separation frame is the "artery" of the whole system. Gas-liquid separation, washing and cooling, alkali liquor filtration, pipeline valves and instruments are all integrated here.

- The whole frame is coated by electrophoresis, which has strong weather resistance, corrosion resistance and corner corrosion resistance.

- The new structural design makes the frame more compact and has higher separation efficiency.

After gas-liquid separation, the purity of hydrogen is always as high as 99.99%, and the purity of oxygen is ≥98.5%.

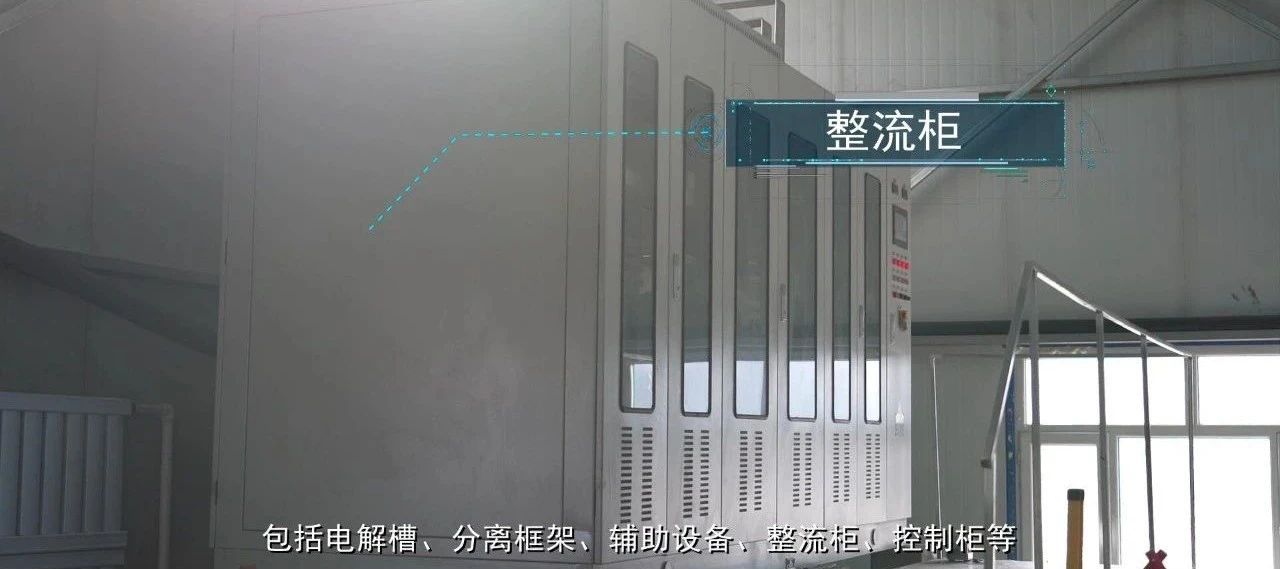

The control cabinet is the "brain" of the whole hydrogen production system and the command center to realize the system functions.

- The control part is mainly completed by PLC, which has the functions of one-button start and stop, data acquisition and full automation of monitoring.

- Hydrogen production will be optimized with the highest efficiency and the lowest life cycle cost.

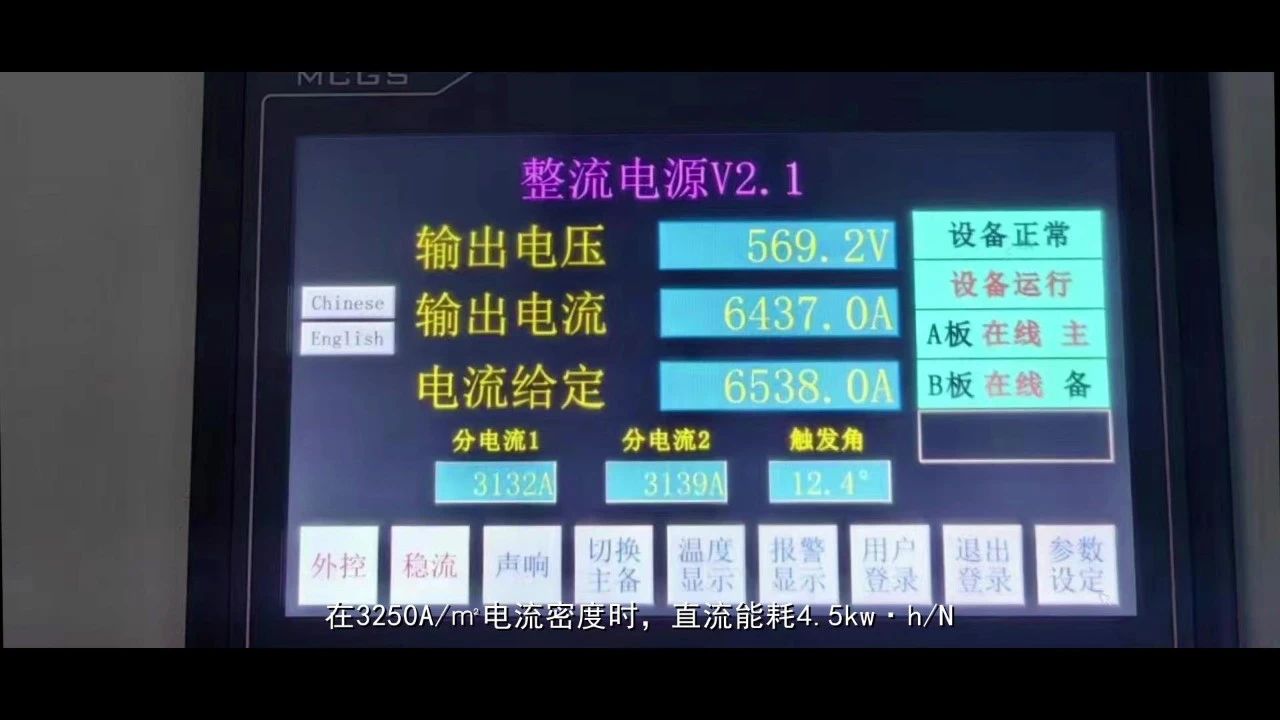

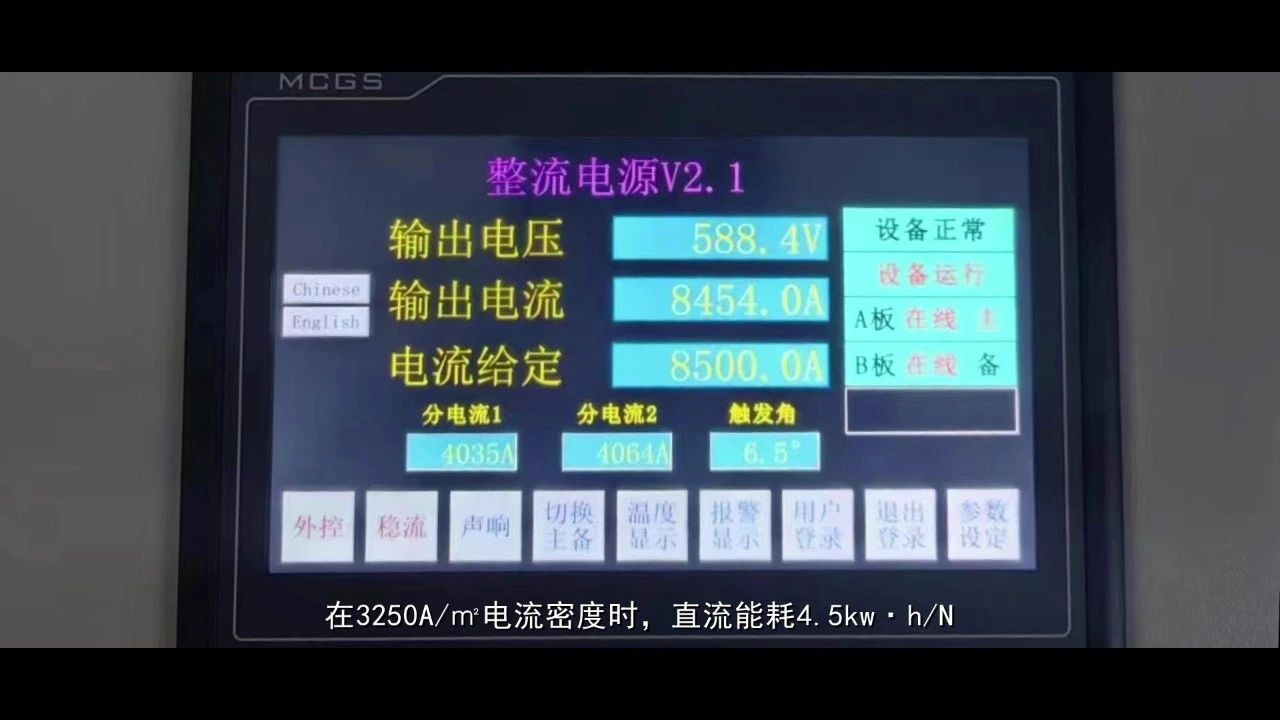

- At the current density of 2500A/㎡, the DC energy consumption of electrolyzer is ≤4.3KW·h/Nm³, and the current energy consumption value is at the advanced level in the industry.

- When the load is 110% and the gas production is 1100Nm³, the maximum working current is 8450A, the current density is 3200A/㎡, and the DC energy consumption is ≤ 4.5 KW·h/Nm³.

"CPU H2" is one of the first equipment enterprises in China to provide on-site large-scale hydrogen production systems. According to different market demands and positioning, it has built its own product series matrix, namely, CPUH2-N/1.6-D, C and P series hydrogen production systems, and provides one-to-one customized hydrogen production solutions.

CPU Hydrogen Power Technology(Suzhou)Co. ,Ltd. has mastered the core technology of electrolyzed water to produce hydrogen, and its hydrogen production equipment has passed many certifications such as ISO and CE, and its characteristics are as follows: hydrogen production range: ~ 1400 Nm³/h; The purity of hydrogen leaving the electrolyzer: 99.9±0.1%; Purified hydrogen purity: 99.999%, hydrogen pressure: 0.1 ~ 3.2 MPa; Water content of hydrogen: ≤ 1ppm.