Application of green hydrogen | Replacing existing gray hydrogen, synthesizing ammonia and methanol

Time:2023/4/19 Tag:The application of green hydrogen,CPUH2,Synthesize ammonia, Synthesize methanol

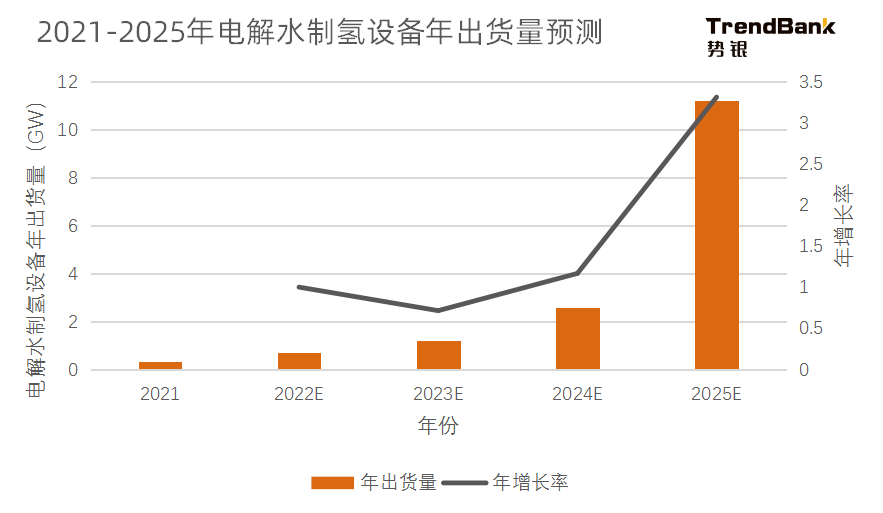

On April 18th, the "GHIC 2023 TRENDBANK GREEN HYDROGEN INDUSTRY CONFERENCE" was grandly held in Ningbo! The theme of the activity is to explore the logic of the "explosive" growth of green hydrogen. According to Shiyin's prediction, the demand for green and renewable hydrogen will reach approximately 1.2 million tons in 2025, and the cumulative shipment of electrolytic water hydrogen production equipment from 2023 to 2025 is expected to reach approximately 15GW.

What is the logic behind the explosive growth in shipments of electrolytic water hydrogen production equipment? In addition, the opening of the event also raised many "soul questioning" questions, such as does ALK still have huge room for technological progress? Will PEM dominate the domestic market like it does abroad? Which application scenarios will first become economically viable While sparking more industry thinking, explore the development direction and strategic layout of the green hydrogen industry together to accelerate the pace of industrial development!

Wang Yaohui, Operation Director of CPU Hydrogen Power Technology (Suzhou) Co., Ltd. attended the event and delivered a speech, proposing that the application of green hydrogen is mainly in the fields of coal chemical and petrochemical industries.

- Direct attack on site

As a major coal consuming country, China has a high dependence on coal. It will be crucial for green hydrogen to gradually replace the existing use of gray hydrogen in the transition from coal to renewable and clean energy. Wang Yaohui believes that the biggest application scenario for green hydrogen is first synthetic ammonia, followed by methanol, which is produced by using coal-fired power for oxygen rich combustion and capturing carbon dioxide. The third application scenario is to use coal gangue and inferior coal to make oxygen rich gas and then prepare natural gas, and finally add green hydrogen directly for hydrogen blending.

Subsequently, Wang Yaohui attended the round table forum and discussed with the guests the breakthrough points of ALK hydrogen production, how to break the current situation of downstream supply chain, and how to balance safety while expanding ALK electrolytic cells.

According to Shi Yin's prediction, by 2025, electrolytic water hydrogen production technology will mainly be applied in fields such as transportation, chemical industry, refining, steel, energy storage, etc. The application of green hydrogen in the above fields can be divided into two categories:

- As a carrier of energy, such as fuel for fuel cell vehicles and related mechanical equipment in the transportation field, and as a carrier of energy storage in the energy storage field.

- As an industrial gas, it is applied in fields such as petroleum refining, chemical synthesis (synthesis of methanol, synthesis of ammonia, etc.), and steel, such as as as a raw material for chemical synthesis or a reducing gas for steel smelting.

Among them, the chemical industry has the highest demand for electrolytic water hydrogen production equipment, mainly concentrated in the fields of synthetic ammonia and synthetic methanol. According to statistics from Shiyin, the demand for hydrogen in the synthetic ammonia field will account for 64% from 2023 to 2025, far higher than other application fields. According to statistics from Shiyin, the planned large-scale green synthetic ammonia projects currently have an annual planned production capacity of over ten thousand tons of green hydrogen, far exceeding the planned production capacity of green hydrogen in other application fields.

△ Figure: Distribution of Green Hydrogen Application Fields

The largest project has an annual planned output of 250,000 tons of green hydrogen (with 632 sets of 1000 Nm³/h alkaline electrolyzer). Therefore, the production of large-scale green synthetic ammonia projects is the main reason for the explosive growth of electrolytic water hydrogen production equipment in 2025.