CPU Hydrogen Makes Significant Progress in Off-Grid Wind-Scenic Coupled Green Hydrogen Production Research

Time:2024/4/22 Tag:CPU Hydrogen, off-grid hydrogen production, technological breakthroughs

Photovoltaic and wind power is a kind of renewable energy without carbon emission, but its energy has the characteristic of volatility, the impact on the safe operation of the power grid system is larger, and the installed capacity of wind power and photovoltaic power available for grid-connection in many areas of the country has reached the upper limit. Using PV and wind power to produce hydrogen by coupling off-grid water electrolysis can not only solve the problem of PV and wind power consumption, but also help the country to deeply decarbonize the industrial, transportation and civil sectors, and realize the national policy of "Carbon Neutral, Carbon Peak".

At present, large-scale electrolytic water hydrogen production equipment with mature technology mainly includes alkaline electrolytic water tank (ALK) and proton exchange membrane electrolytic water tank (PEM). although the PEM electrolytic water tank can match the volatility of wind power and photovoltaic, the membrane electrode catalyst relies on platinum precious metals, and 90% of the world's platinum mines are located in the British Commonwealth countries such as South Africa, Canada, etc., and the high-quality proton exchange membranes are mainly supplied by the U.S. DuPont, resulting in the price of about five times of the ALK electrolytic tank, which is the most expensive. The result is that the price of PEM electrolyzer is about 5 times higher than that of ALK electrolyzer. Moreover, against the background of trade friction between China and the United States, the large-scale development of PEM water electrolysis technology involves great energy security risks. Alkaline electrolyzer does not need to use precious metal catalyst, and the core components can be realized domestically, so it is the best choice for large-scale production of green hydrogen.

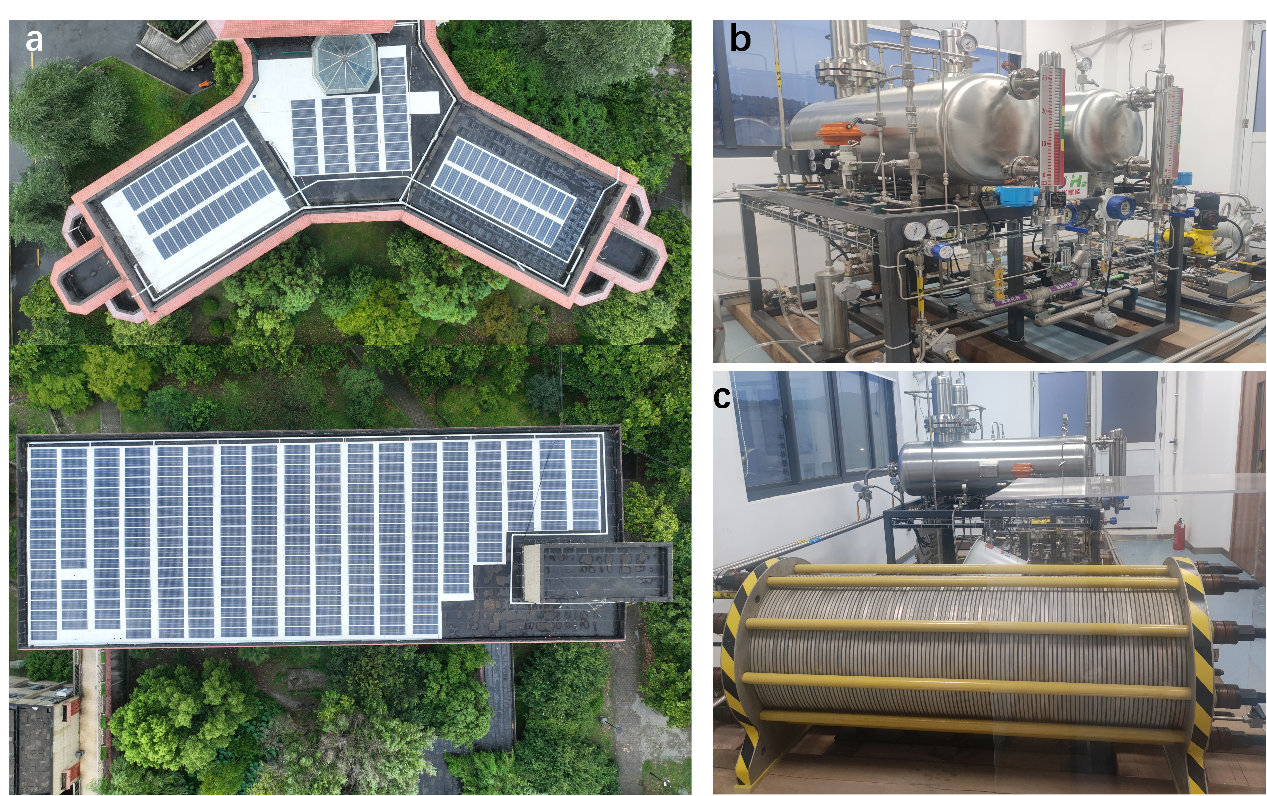

(Rooftop off-grid photovoltaic hydrogen production system)

CPU Hydrogen has formed a partnership with Gusu Laboratory, Goodway Technology Co., Ltd. and Suzhou University of Science and Technology to develop an off-grid photovoltaic electrolysis system in Suzhou. This initiative aims to overcome the limitations of green hydrogen production. The system comprises a wide-load power electrolyzer and an off-grid hydrogen generation power supply. The system enables the production of green hydrogen using an off-grid photovoltaic current-driven alkaline electrolyzer, with a purity of over 99.98% without purification.

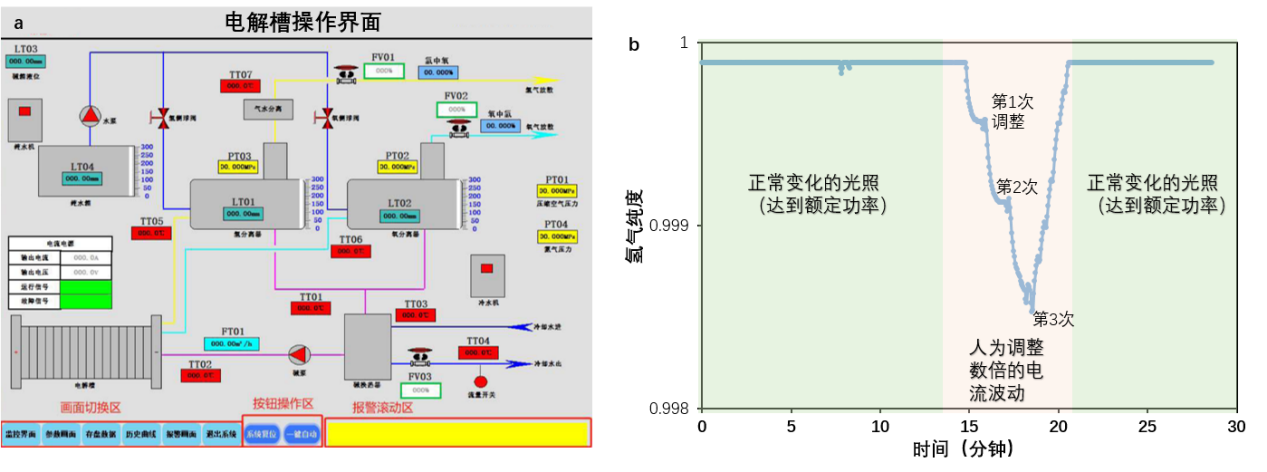

According to the characteristics of off-grid PV and wind power volatility, CPU Hydrogen has customized a wide load power electrolyzer system with a rated input voltage of 200V, DC energy consumption of ≤4.1 kW-h/Nm3, and a current density of 3200 A/m2, which can operate dynamically within the range of 30%-110% of the rated load, and is able to match the fluctuating characteristics of PV current. Under normal light intensity fluctuation, the hydrogen exported from the electrolyzer can be stabilized to 99.98% without purification, and the DC energy consumption is as low as 4.0 kW-h/Nm3under the best working condition. The electrolyzer can also withstand extreme current disturbances and respond to 5 times the current fluctuation within 30 seconds. During the experiment, the entire PV hydrogen generation system can reduce 100% of the rated load power to 30% in 30 seconds, or increase 30% of the load power to 100% in 30 seconds, during which the hydrogen purity is always maintained above 99.8%.

(off-grid photovoltaic water electrolysis for hydrogen production experiment)

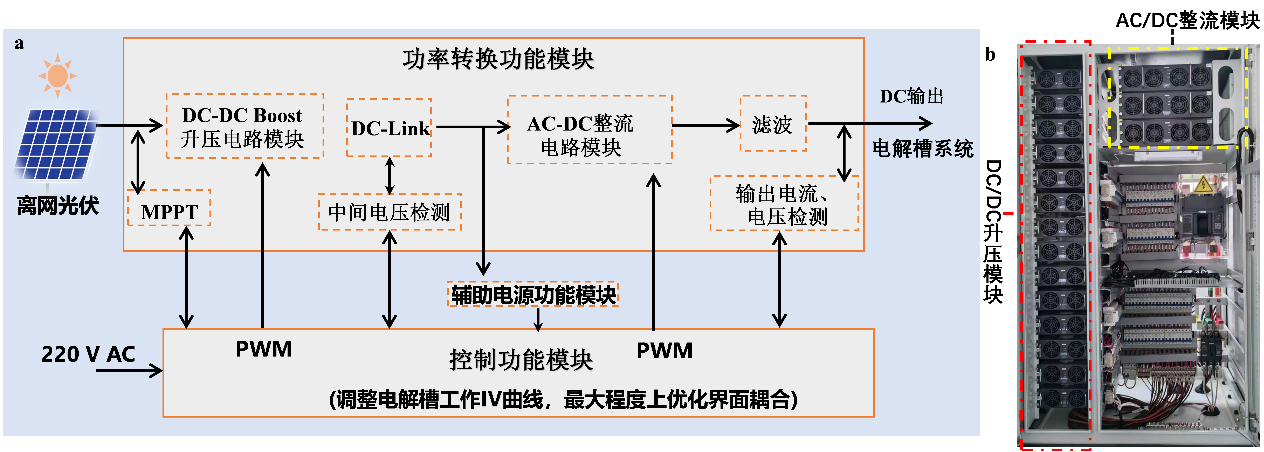

Based on the characteristics of light energy volatility, academician Tang Shuxian's team from Suzhou University of Science and Technology has developed and designed a new type of off-grid photovoltaic hydrogen production power supply by using IGBT scheme, reserving alternating current (AC) interface, integrating DC/DC and AC/DC power conversion module, dynamically tracking the maximum power point (MPP) of photovoltaic, and realizing the coupling and conversion of DC and AC by optimizing the software algorithm of the system. By optimizing the system software algorithm to convert direct current (DC) and alternating current (AC) into direct current (DC) required by the electrolyzer, the hydrogen production power supply can stably output a voltage of about 200V, and dynamically change the output current according to the change of light intensity, thus adjusting the IV curve of the electrolyzer, optimizing the interface coupling to the maximum extent, so that the efficiency of PV DC converted into the DC required by the electrolyzer can reach 96%, which can perfectly match with the operating conditions of the electrolyzer, and the purity of hydroxide and oxygen in the process of operation can reach the design standard of the electrolyzer. The purity of hydrogen and oxygen during operation reaches the design standard of the electrolyzer. In the future, the AC interface of the hydrogen production power supply can be connected to wind power, realizing pure off-grid wind and solar hybrid coupling to produce green hydrogen.

(200V hydrogen production power supply system designed based on IGBT scheme)

In the current context of global energy transition, how to produce affordable green hydrogen is receiving more and more attention. In Xinjiang, Inner Mongolia and other regions rich in wind and light resources, the power generation cost of photovoltaic and wind power has been reduced to RMB 0.1 yuan/kWh. According to the estimated price of electricity, the price of hydrogen produced by alkaline electrolyzed water using pure off-grid wind/photovoltaic can be reduced to RMB 9 yuan/kg H2, which is undoubtedly a more competitive price compared to the traditional hydrogen production method.

The development of off-grid wind/photovoltaic hydrogen production technology is set to become a significant trend in the future of energy. CPU Hydrogen's alkaline electrolyzer, which has a wide power load and is designed for off-grid hydrogen production, will have a significant impact on the development of green hydrogen in China. Looking ahead, CPU Hydrogen will continue to devote itself to innovative research and development in this field, contributing to the construction of a clean and sustainable energy future.