CPU delivers first square hydrogen production system

Time:2025/3/18 Tag:CPU Hydrogen, Voltvista, First set, Delivery

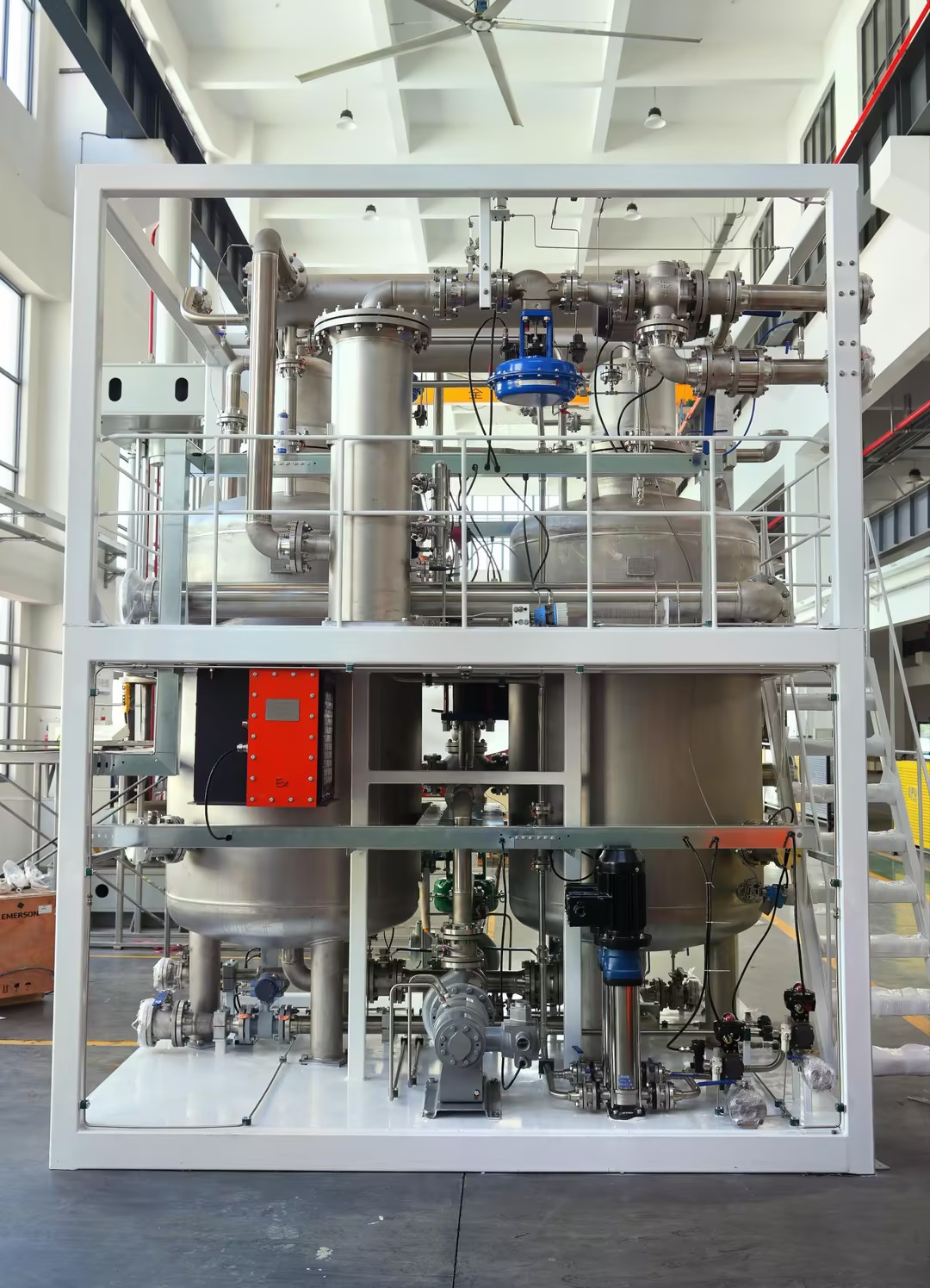

On March 17, 2025, the Suzhou Xiangcheng Hydrogen Energy Industry Landmark, a key facility in the local hydrogen energy sector, witnessed a significant event. The CPU Hydrogen Energy Production Base, a pivotal component of this landmark, was bustling with activity. The first 1,000Nm³/h "Voltvista" square hydrogen production system was loaded onto a special vehicle and sent to Jilin Province. This system will be deployed in a wind - power - to - hydrogen project for a leading domestic company.

- Lightning - Fast Delivery: Achieving a "Technology - Manufacturing" Full - Chain Closed Loop

- Three Major Surpasses: Redefining Alkaline Electrolysis Technology Boundaries

Since its release in August 2024, the "Voltvista" series of square electrolyzers from CPU Hydrogen Energy has garnered significant attention. With excellent performance and cutting - edge technology, it has redefined alkaline electrolysis technology boundaries through three "surpasses." The system can be expanded to a maximum of 3,000Nm³/h, and its modular design supports a three - level jump in production capacity. It can operate stably at 15% of its rated load, effectively solving the problem of matching green electricity fluctuations. The Plug-in unit slot design reduces installation and maintenance costs by 60%. These features make the "Voltvista" series ideal for large - scale hydrogen production and applicable in synthetic ammonia, green methanol, and electronic fuel fields.

- Technology Implementation: Creating Customer Value Through Full - Chain Synergy

The delivered 1,000Nm³/h square hydrogen generation system adopts a container - mounted skid package design for installation and transportation. Once operational, each device can produce 1,000Nm³/h of hydrogen with a purity exceeding 99.5%. It has a wide load regulation range of 15% - 110%, aligning well with local wind power output curves. As the first order of the "Voltvista" series, it will be utilized in a wind - power - to - hydrogen demonstration project, assisting customers in achieving large - scale green hydrogen production.

- Continuous Cultivation: Igniting the Engine for High - Quality Green Hydrogen Development